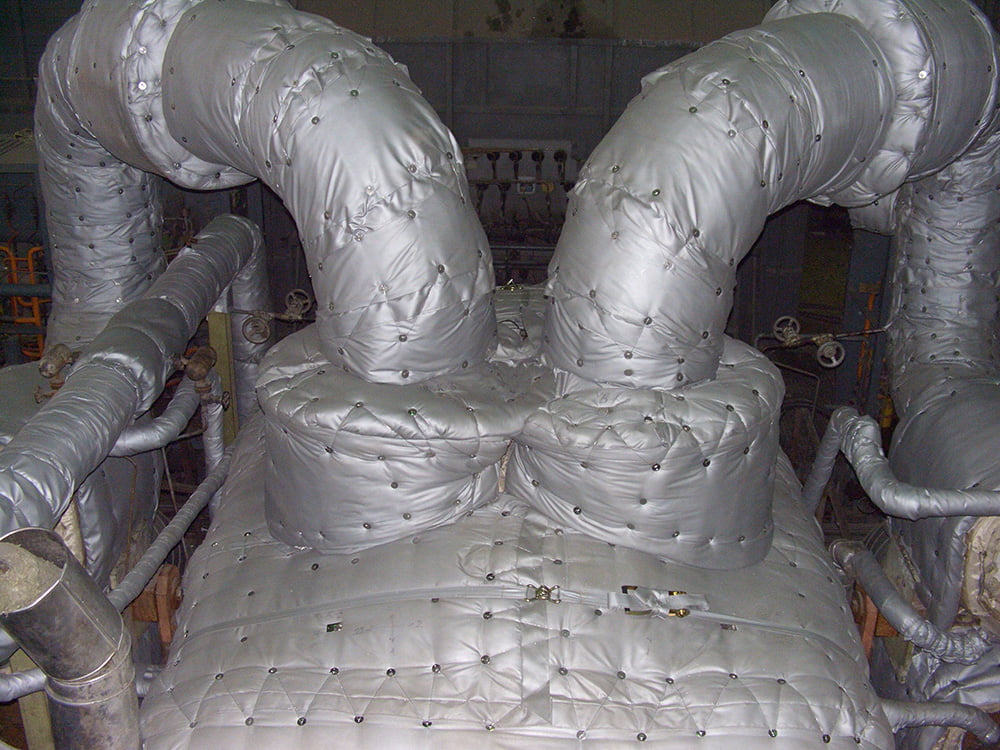

Vanomat Valve Jacket

Vanomat Valve Jackets, which is developed with soluble pad system, became most preferred insulation since it provides energy saving as well as it enables worker’s health and safety, and provides time saving due that it is easily mounted and dismounted (minimum loss in production), and enables usage of state of art technology products. It provides significant amount of energy saving in hot line valves without insulation application.

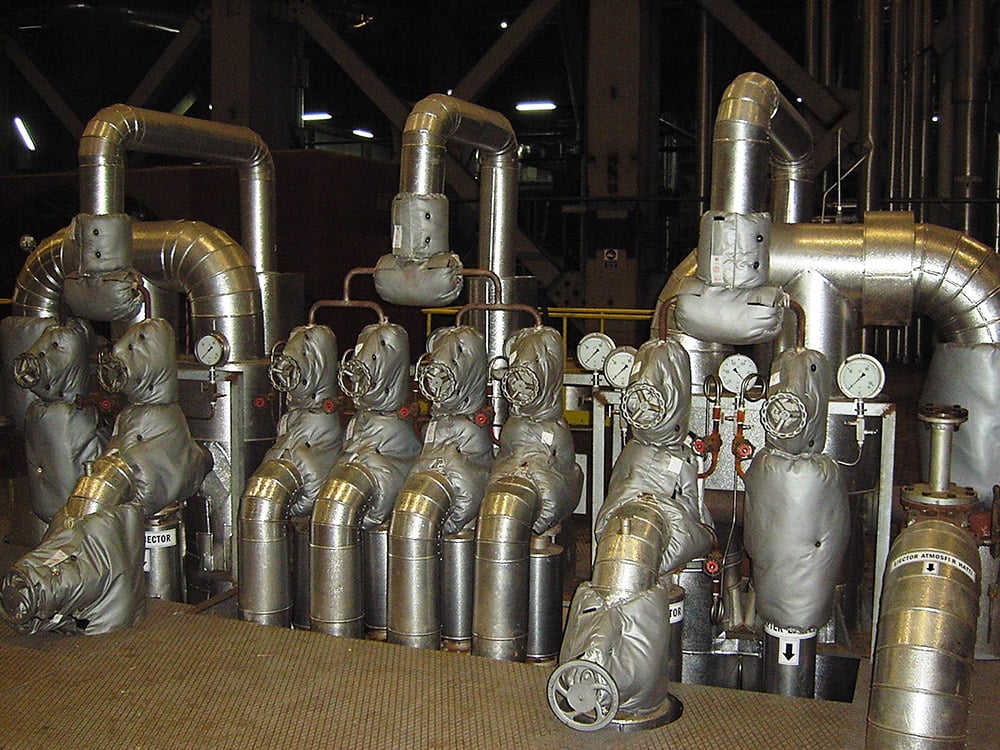

Heat dissipation from a valve is equal to dissipation from a pipe at least 1m in length, which such valve is connected. (Source: Department of Environment Energy Efficiency Programme). When number of valves used in factories is considered, it can be assumed that heat dissipation is existing equal to heat dissipation from hundreds of meters of pipe. Valve jackets, which are designed in mountable and dismountable manner, can be repeatedly mounted and dismounted according to malfunction incidents.

ADVANTAGE:

- Reduces heat dissipation.

- Since it reduces outer surface temperature, it reduces downtimes occurred due to work accidents, enhances work safety.

- It is easy to be mounted; it can be mounted without requiring any special knowledge.

- It is easy to be dismounted; it can be dismounted in a very short time and mounted again.

- It can be mounted and dismounted repeatedly. There is no need to use new materials as at each time as in fixed insulation application.

- It is required to make expense for insulation for once; it is used for very long time.

- Since outer fabric of valve jackets are made of silicon, they can be used in outer environment; it prevents ingress of liquids such as oil, fuel etc. and damages to insulation felt.

TECHNICAL PROPERTIES :

Glass Fiber Fabrics :

Silicone coated fabrics or PTFE coated glass fiber fabrics are mainly used in valve jackets. Ingress of liquids, oil, fuel etc. by coating over weaved fabric with silicon or PTFE. Glass fiber fabric can be used at temperatures up to 500-550 °C.

Continuous use temperature of silicon coated glass fiber is 230 °C, and PTFE coated fabric is 300 °C. Glass fiber fabrics that are resistant to higher temperatures can be used according to working conditions (up to 1000 °C). Fabrics are in A1, A2, B1 Nonflammable Materials Group in accordance with German Norm DIN 4102.

Insulation Material : Insulation felt in appropriate thickness is placed in valve jacket in order to reduce heat dissipation. Appropriate insulation felt and insulation thickness are determined by our technical staff according to operation temperature and desired heat dissipation through thermal calculations made by computer. Glass fiber, rock wool and Filomat insulation felts in various thicknesses and densities are used as insulation felt. Used insulation felts are in A Class non-flammable materials group according to German Norm DIN 4102.

Accessories:

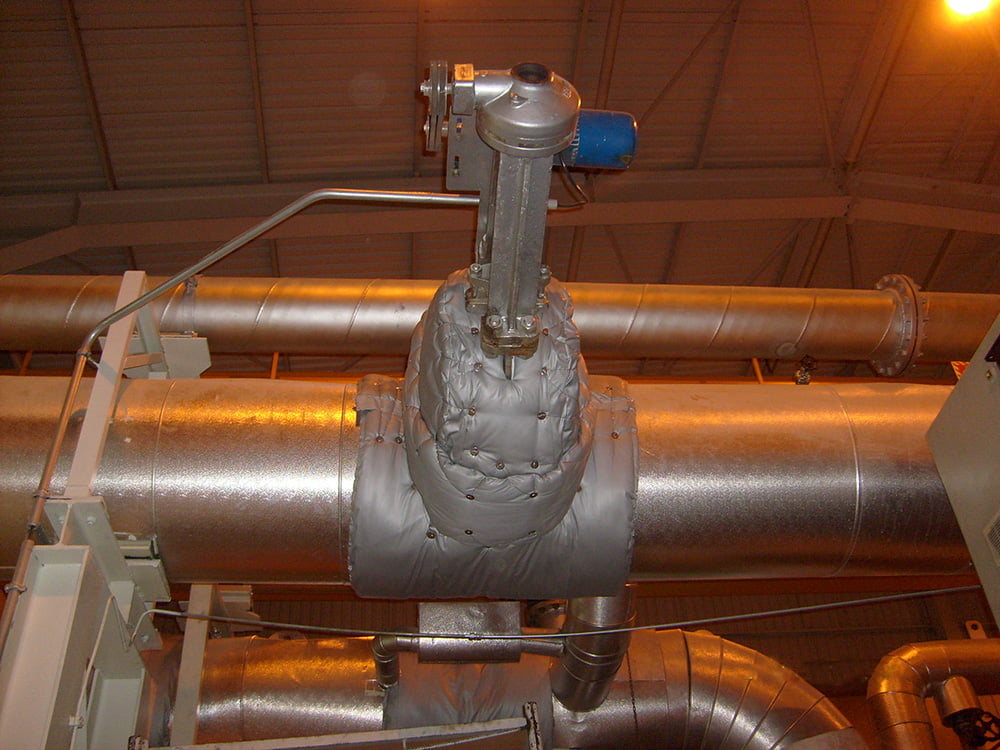

Stainless steel fasteners are used in order to mount valve jacket and prevent disintegration of insulation felt. Fastening wires made of stainless steel are passes through these fasteners and valve jacket is mounted to its place easily.

Alternatively, valve jackets can be manufactured with Velcro bands as well.

In sewing of jackets, glass fiber sewing threads or para-aramid sewing threads, which are resistant to high temperatures are used.

There are squeezing threads at edges of valve jackets in order to prevent heat dissipation from sides and to facilitate mounting works. Since there is apotential to be in contact with surface without insulation, these threads must be heat resistant. Therefore, these squeezing threads that are made of glass fiber should be used.