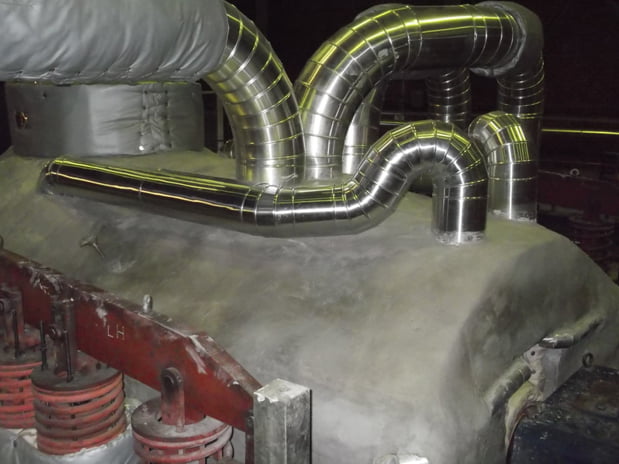

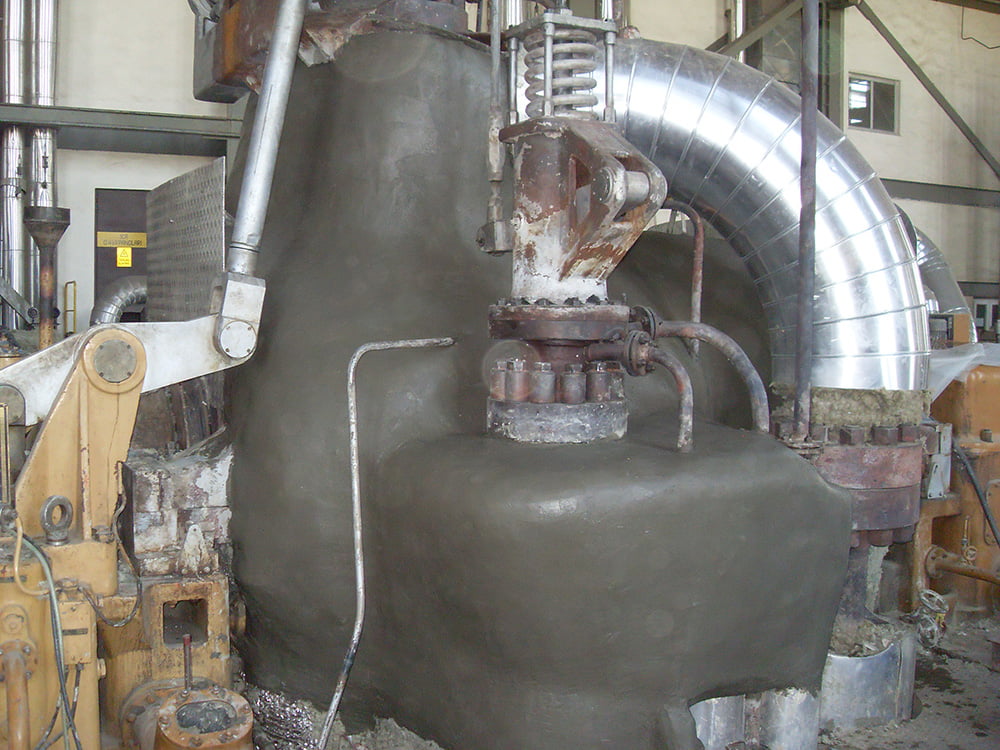

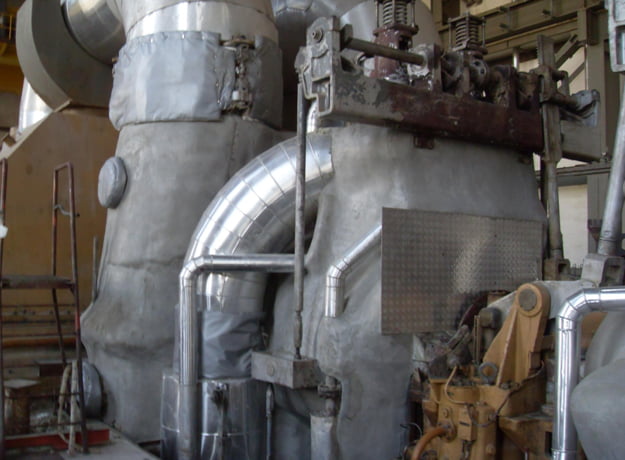

Turbine, Machine and Equipment Insulation with Spray Insulation Method

Insulation with spray method provides energy saving, as well as it is preferable insulation method in respect of that it provides worker health and safety, forms a robust and rigs insulation surface. Particularly, it is preferred in steam tribunes that do not require maintenance, and is not dismounted for long time and do not opened frequently.

In spray method, materials that are in granule form and resistant to high temperatures (especially rock wool) are applied by processed through a special machine. In order to apply spray on turbines or their equipment, bracing members and gauzes are mounted. Granulated insulation material is passed through spray machine and complete coating of equipment body is ensured. Entire body is coated with high-density rock wool without leaving any gap. Insulation process is finalized by applying special plaster and oil repellent paint over rock wool.

ADVANTAGES

- Commissioning times are short and insulation performance is high in turbine body and machine insulation applications.

- A massive and without space insulation is applied on machines and equipment.

- Since used materials have low thermal conductivity coefficient, heat insulation is realized with high efficiency.

- It works flawlessly for long years. Does not require extra maintenance.