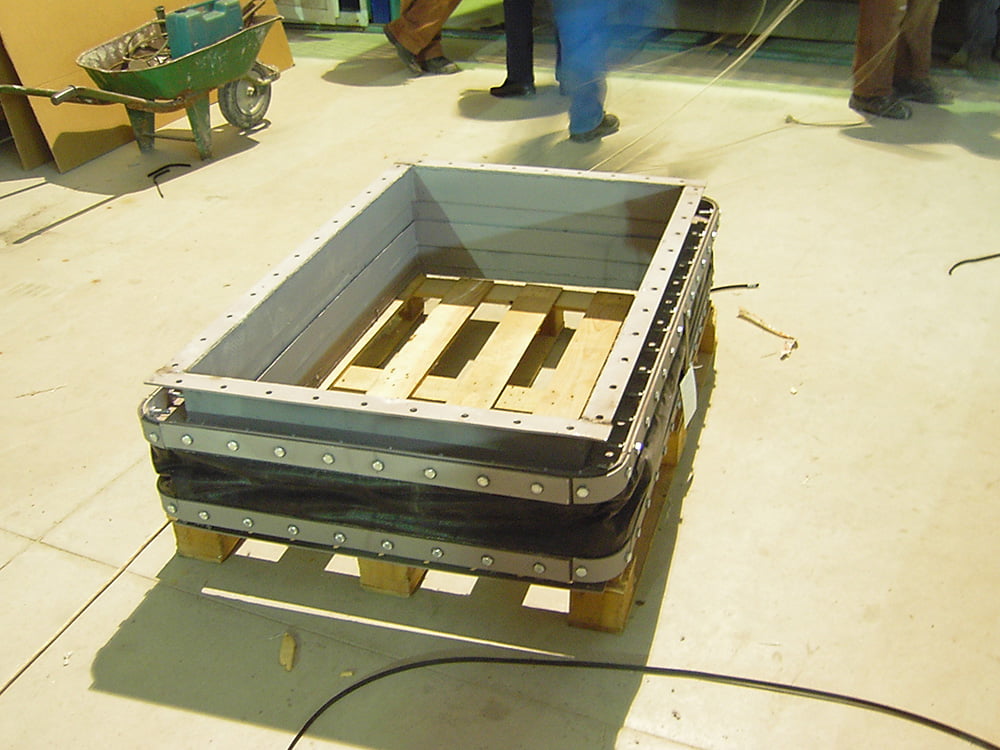

Textile Compensator (Expansion Joint)

Textile compensators are flexible connection members that are used in order to prevent movements and vibrations occurred in ducts due to temperature changes. Impermeability element is the most important component of compensator. Impermeability element should be resistant against pressures from inside and outside and chemical attacks. And should be flexible to absorb thermal movements at the same time. At the present time, there are 3 types of compensators and multi-layer textile compensators have significant advantages compared to others 1. Textile Compensators 2. Rubber Compensators 3. Metal CompensatorsAdvantages