Established in 1980, Kıvanç Group continues its activities in 3 divisions; Safety, Engineering and Mining.

Besides, AKATEK (a Kıvanç Group company), is a technical yarn & fabric manufacturer serving to heat & flame protective garment manufacturers. At our ring spinning mill in Antalya Organized Industrial Zone with a capacity of 10,800 spindles, mostly flame-resistant technical yarns are produced with an annual capacity of 1,000 tons; and 1.5 million meters of technical fabric are produced annually on our 12 high technology weaving looms. The fabric used in the suit of Türkiye’s first astronaut, Alper Gezeravcı, was proudly manufactured by Akatek.

In Safety Division, personal protective clothing against heat and flame, static discharges, arc flashes, molten metals, welding spatters and chainsaw are produced.

At our Sinop factory, we manufacture personal protective garments such as firefighter suits, search and rescue clothing, and heat and flame resistant, antistatic protective clothing for workers in refineries, petrochemical plants, pipelines and storage facilities. We also produce protective garments for the iron and steel industry against molten metal splashes, as well as protective clothing against arc flash for power generation and transmission lines. Additionally, products such as wildland firefighting clothing, chainsaw protective clothing, pilot coveralls, tanker crew uniforms, and camouflage apparel are manufactured for military and security forces.

Kıvanç Group established Turkey’s first heat laboratory in the field of personal protective clothing. Following a second investment, a physical test laboratory has become operational, where raw materials and finished products are tested in accordance with EN and ISO standards. All tests prior to CE certification are conducted to enhance product reliability and accelerate processes. The laboratory also supports R&D activities.

Thanks to the barcode system integrated into our ERP (Enterprise Resource Planning) software, which has been in use since 2009, full traceability is ensured, and all product processes can be monitored. The work order number on the label of each garment produced by our company allows tracking of the production date, materials used, as well as the date, lot number, and supplier of the raw materials.

Kıvanç Group is the first personal protective clothing manufacturer in Turkey, having ‘Product & Third Party Liability Insurance’. The cost of damages that may arise from the incidents to be encountered by the people using our garments due to material and faulty workmanship have been guaranteed within this insurance.

In Engineering Division, thermal insulation applications to reduce the heat loss are done by using high temperature resistant glass fiber based materials. We manufacture removable insulation pads for turbines, plastic injection molding machines, textile dying machines, exhaust parts of vehicles, valves etc. Correct materials are used by calculating the heat loss, minimum thickness of insulation, surface temperature etc. Thermal imaging cameras are used to find the heat loss areas.

Machine equipment insulations, textile compensators, fire blankets, smoke screens and welding blankets are produced by using glass fiber based materials.

In Mining Division, Silica (Quartz) Sand and Musselstone are extracted and processed at our facility located in the Süloğlu district of Edirne.

- Silica (Quartz) Sand is used in potable and waste water filtration, in construction chemicals, in railroads as a skid preventing sand, in hippodromes, in pitch and sports fields and in many other fields.

- Musselstone is a compact stone that consists of limestone, silica and fossil sediment (such as clams and mussels). It is in light beige color, highly or partly porous with fossil according to its formation. Musselstone has been used frequently in artistic works that require aesthetic, elegance and art such as interior spaces, coves, columns, jambs, exedras, wall copings, fire places, landscaping, reliefs, crown gates, portal, altars, minibars, birdhouses, benevolence stones. Nowadays, it is used for restoration of historical buildings, and in new buildings, kiosks, villas waterfront residences, garden walls, walking trails, and in similar places.

Vision

To be a leading company that guides the industry, which all its stakeholders are proud of with its experience, production and technical knowledge as well as its quality and R&D activities on all activities that it engages in.

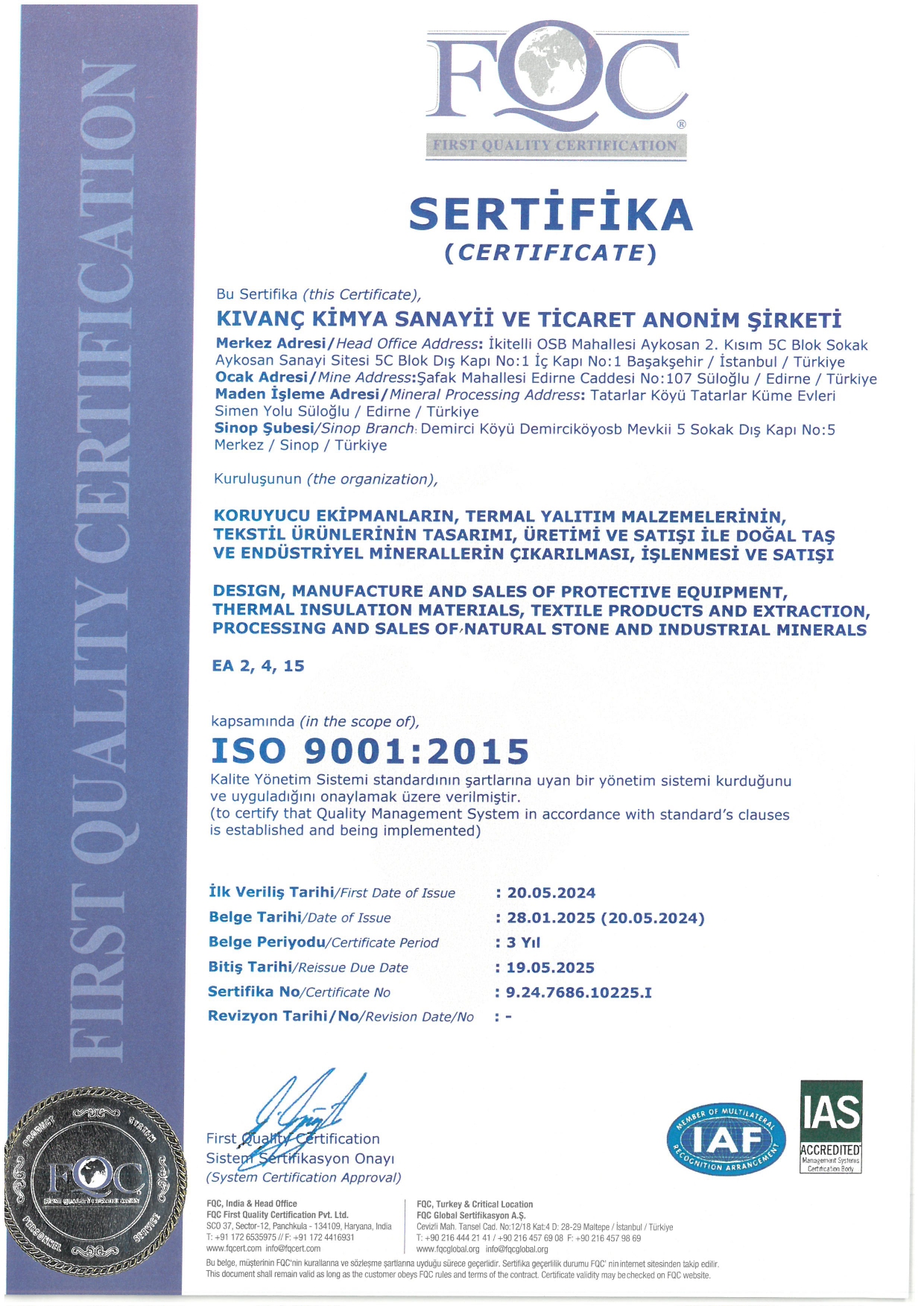

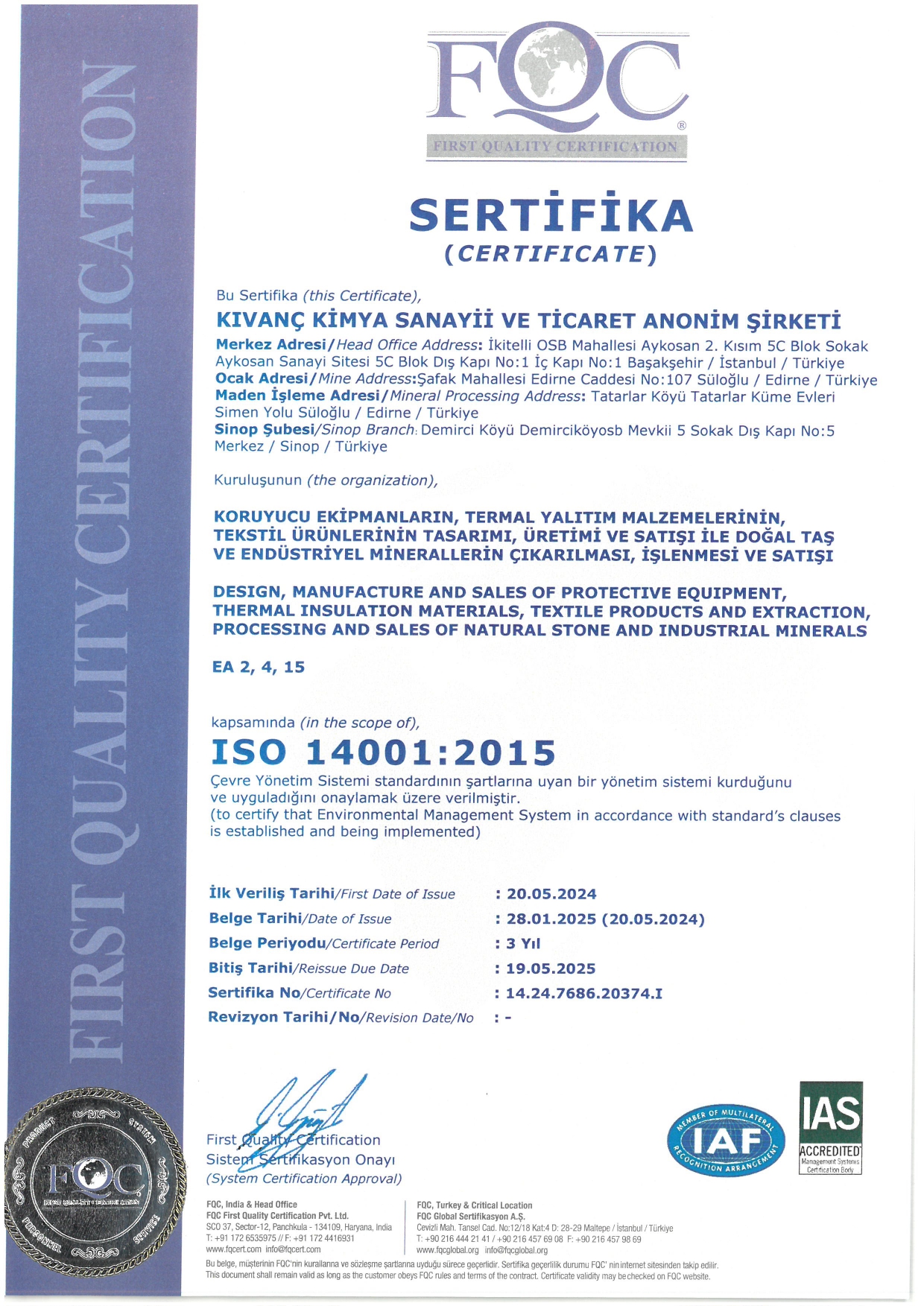

Certificates

We carry out our activities in a dynamic structure with accordance legal requirements and the requirements of our management systems

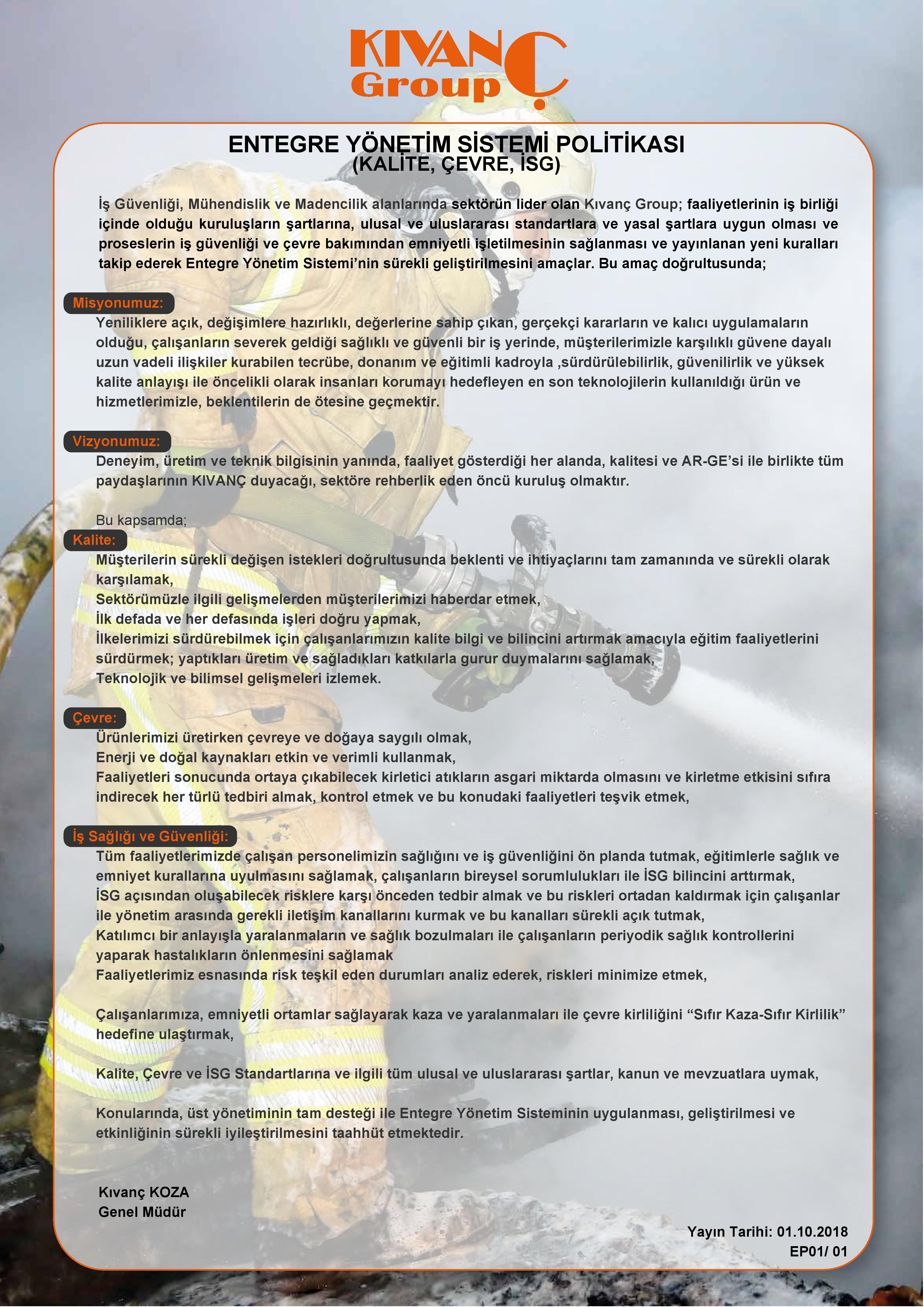

Integrated Management System Policy

We proceed in line with the environment and human-oriented policies we have determined within the framework of Quality, Environment, Health and Safety.

Mission

To be an innovative, ready for change, value adopting company where realistic decisions and permanent applications are available, with a healthy and safe working environment that employees fondly come, which is capable to establish trust based relationships with its customers, which mainly aims to protect persons with its experience, knowledge and trained staff and its understanding of sustainability, reliability and high quality, and to go beyond expectations with our services and products provided with state o art technology.